A new University of Virginia-inspired public benefit company with a global health mission, MadiDrop PBC, has opened administrative offices and a small production facility in Charlottesville, company officials announced today at the 2015 Water and Health Conference, being held this week at the University of North Carolina’s School of Global Public Health.

The technology transfer company will produce ceramic water disinfection tablets called “MadiDrops” for people in developing countries who have poor access to clean drinking water. The company is an outgrowth of a project started in 2012 at UVA through a nonprofit organization called PureMadi. “Madi” is the Tshivenda South African word for water.

The MadiDrop tablet, which uses silver to disinfect water, was developed and extensively tested by UVA scientists and students. It is inexpensive to produce and can repeatedly disinfect water for up to six months by simply resting in a 10-liter household water storage container.

“We wanted to maximize production and distribution of MadiDrop, to make this technology available to the world at very low cost, so we developed this public benefit company,” said James Smith, a UVA civil and environmental engineer who played a key role in developing and testing the water disinfectant. “The goal of MadiDrop PBC is to maximize health benefits, not to maximize profits.”

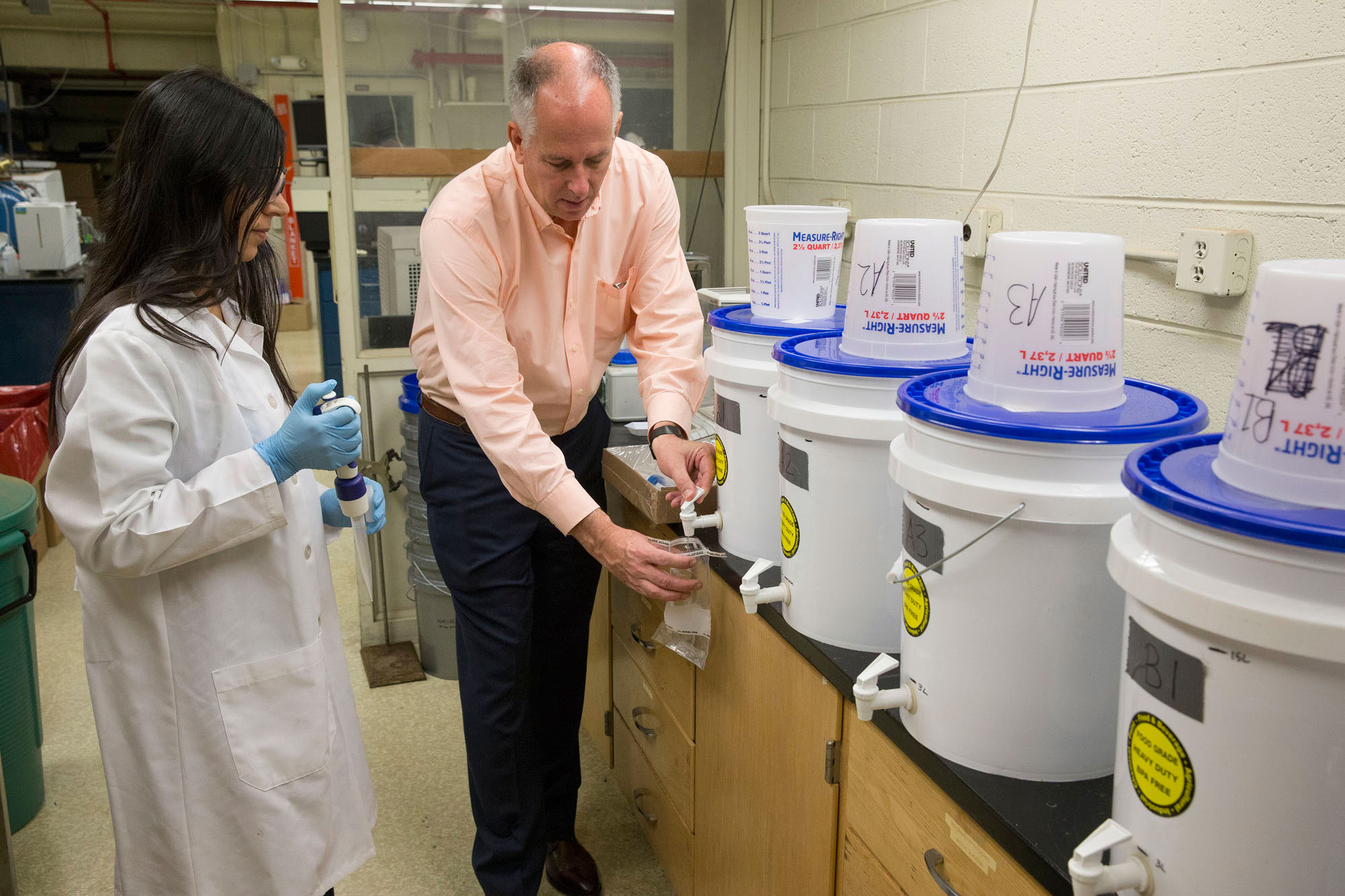

James Smith and Rekha Singh, a research scientist in Smith’s lab, demonstrate use of the MadiDrop tablet.

The company will begin production in January and produce about 100,000 to 200,000 MadiDrop tablets in its first year, for sale primarily to non-governmental aid organizations such as the U.S. Agency for International Development, the International Rescue Committee, Catholic Relief Services and Habitat for Humanity. Those entities then would distribute the tablets to developing countries as needed, particularly during times of crises such as after a natural disaster. The tablets also would be available in the United States.

MadiDrop PBC expects to eventually build capacity to produce 1 million to 2 million MadiDrops per year. The company intends to explore domestic applications as well.

“The Charlottesville factory will be a clean production facility with a simple production process, employing just a few workers in the beginning,” Smith said. “We plan to keep costs down so we can make MadiDrop affordable in developing countries where the need is greatest.”

The company is starting with seven employees, and will ramp up to about a dozen employees next year.

“The goal of MadiDrop PBC is to maximize health benefits, not to maximize profits.” - James Smith

Smith expects MadiDrop tablets to cost less than $10 each, and possibly as low as $5 each. With an effective use life of about six months per tablet, this is significantly cheaper than single-use chemical water purifying tablets, which cost $50 to $100 for a six-month supply. According to Smith, MadiDrop tablets are inexpensive to produce, are durable, reusable and easy to package, transport and ship.

Unlike small chemical tablets that dissolve in water and leave a chlorine aftertaste, MadiDrop is made of a continuously reusable ceramic that is simply placed in a water vessel, such as a bucket, and left there for several hours or overnight. Silver ions are gradually released from the tablet, killing pathogens by penetrating cell membranes and disrupting cell division.

Extensive testing at UVA labs show that the tablet causes better than a 99.99 percent reduction in such infectious water-borne bacteria as Vibrio cholera, Escherichia coli and other coliform bacteria. The MadiDrop also is effective at reducing the infectivity of protozoan pathogens including Giardia lamblia and Cryptosporidium parvum, all of which cause severe diarrhea, vomiting, dehydration and potential long-term growth and cognition deficiencies. These pathogens are particularly devastating to children and people with AIDS.

Smith said that most of the revenue from sales of MadiDrop initially will be fed back into the company to fuel production expansion. Public service-minded investors will become shareholders and eventually make small profits. MadiDrop PBC will provide profit-sharing for employees and the highest-paid employee will never make more than 15 times the salary of the lowest-paid employee.

The company has raised an initial round of funding from private investors. “It’s a different mindset, a non-profit/traditional company hybrid – profit-making for the public good,” Smith said. “We are actively raising additional capital to help us bring this innovative public health product to people in need around the world.”

MadiDrop PBC’s administrative office is located on Allied Street in Charlottesville and the production facility is on Avon Street. For more information, click here.

Media Contact

Article Information

October 26, 2015

/content/new-company-produce-water-purifying-tablets-invented-uva