With worries about a worldwide water crisis looming, the process of turning salty water into drinking water, long regarded as expensive, is looking up. A University of Virginia engineering professor is exploring ways to improve polymer membranes to make desalination simpler and less expensive.

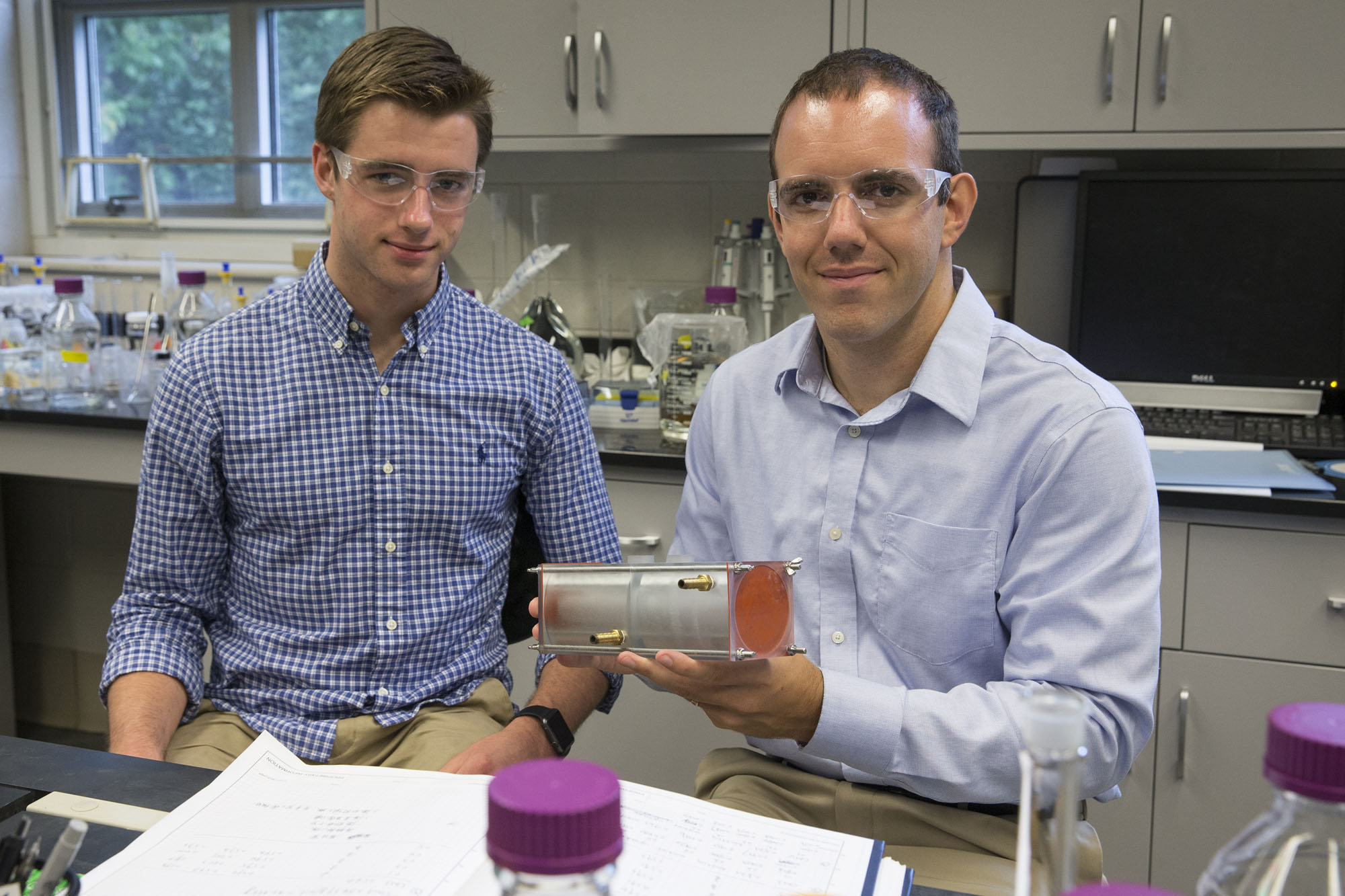

Geoffrey M. Geise, an assistant professor in the Department of Chemical Engineering, believes the membranes can also be used to help create and store clean energy.

“Membranes purify water by blocking, to a large extent, salt and/or contaminants from passing through,” Geise said. “The desalination membranes that we study work by allowing water molecules to move more rapidly through the polymer compared to salt, resulting in less salt on the product side of the membrane.”

In general, salt dissociates into ions that pick up and hold onto water molecules in a way that makes a hydrated ion larger than a single water molecule. Water moves faster through the membrane compared to the salt (or ions) because it is smaller than the hydrated ions. Additionally, ions are less energetically favored in the membrane phase compared to the water phase, resulting in a situation where ions prefer to stay out of the polymer, which also results in effectively slower salt transport compared to water. By changing the polymer chemistry, Geise’s team is trying to maximize the separation efficiency based on these mechanisms.

While water and energy research are being conducted in many places around the world, Geise thinks his group has an edge.

“I believe our team at UVA brings a unique combination of experimental and computational research capabilities that will make it a leader in this area,” he said. “We can apply these same principles to other contaminants or pollutants, but a key challenge is understanding how to fine-tune material chemistry to maximize the selectivity of the polymer. That would make water purification as efficient as possible.”

A polymer is a material made up of large macromolecules that are chains of much smaller repeat units. Changing the chemical nature of the repeat units changes the properties of the overall polymer. A polymer membrane is a film of solid polymer that is designed to generally act as a barrier.

“In our work, we deal with semi-permeable membranes that are designed to act as a barrier against transport of certain molecules while allowing transport of other molecules,” Geise said.

Geise said he and the researchers in his laboratory are working on developing a better understanding of how to minimize the amount of salt, or ions, that travel through membranes without affecting the amount of water that passes through. He said they can adjust the polymer structure to control the speed of salt movement compared to the speed of water movement through the polymer.

“If salt diffuses much slower than water, then desalination occurs,” he said.

But the researchers can also restrict salt passage by blocking the salt from entering the membrane in the first place. This can be done by designing a polymer such that salt strongly prefers to remain in the salty water feed solution, as opposed to entering the membrane and moving through it to the product solution.

“If the salt never gets into the membrane, it cannot move through the membrane and desalination occurs,” Geise said.

More than half of existing desalination technologies on the market rely on reverse osmosis membranes, where water is pressurized on the feed side of the membrane, and this pressure causes water to move through the polymer. Other technologies, such as electrodialysis, require electrical energy to drive the separation.

“By making membranes that are more selective, we can reduce energy consumption by reducing pressure requirements for reverse osmosis or electrical energy requirements for electrodialysis,” Geise said.

Geise’s research not only looks at water desalination, but also explores how to generate clean energy using similar membranes. Many of the energy generation and storage applications with which Geise is working, however, are part of emerging technologies that are not widely used today.

The emerging energy generation technology “reverse electrodialysis” turns the electrodialysis process around and uses differences in salt concentrations on either side of a membrane to generate electrical power.

“In energy-storage technologies, such as flow batteries, membranes are used to separate the different compartments of the battery while still allowing ions to pass through the membrane in order to enable the battery to work,” Geise said. “In batteries and energy generation, unlike desalination, we typically want to enable ions to move through the membrane while effectively blocking transport of other components of the system.”

The worldwide need for increased access to purified water and clean energy drives his research, Geise said.

“Membranes enable many technologies in this area, and improved membranes will contribute to more efficient water purification and enhanced renewable energy resources,” he said.

Media Contact

Article Information

October 20, 2015

/content/improved-polymer-membranes-may-simplify-desalination-reduce-cost