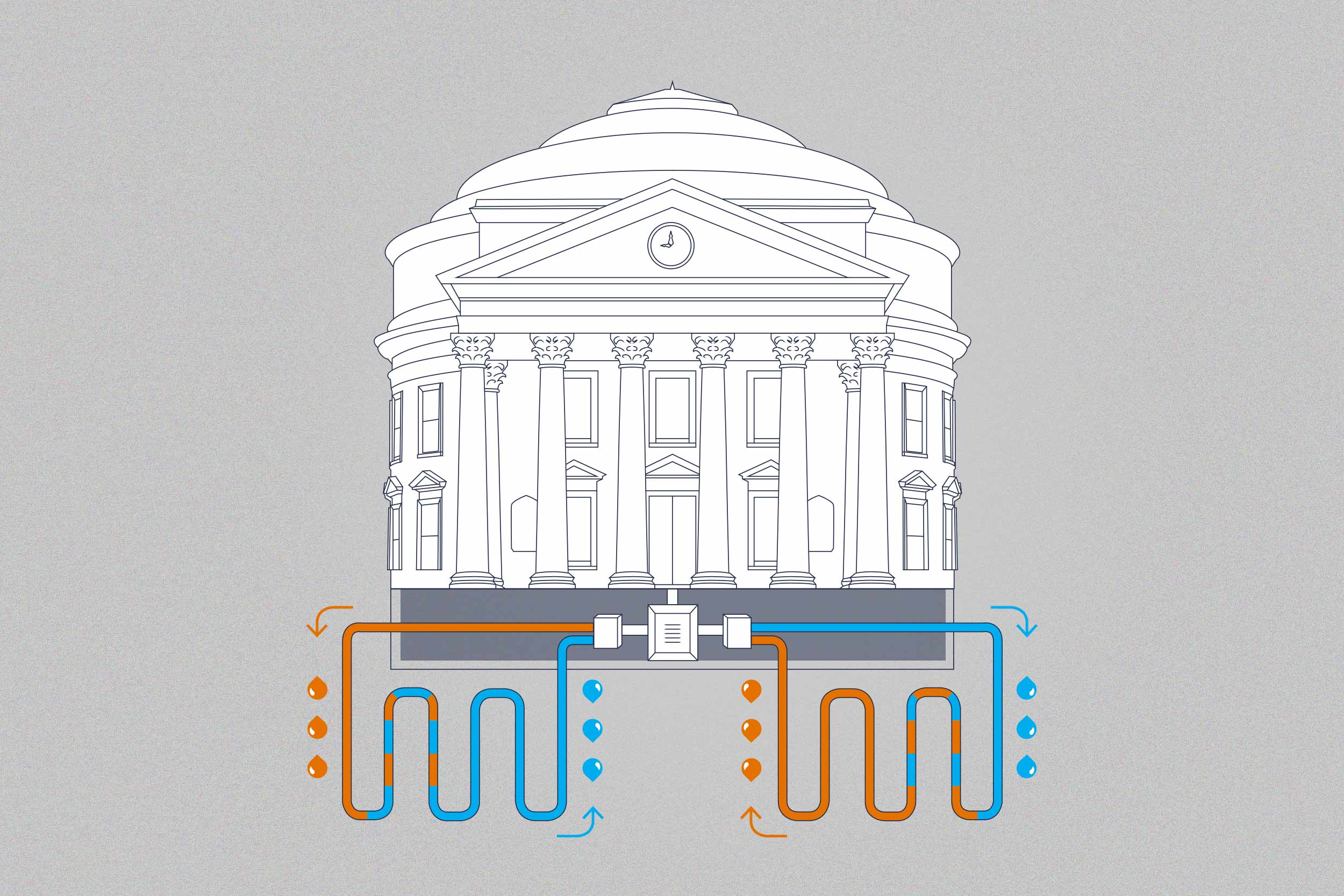

The new Paul and Diane Manning Institute of Biotechnology at the University of Virginia will be warmed with geothermal heat, which stores energy in underground wells.

The recently announced Manning Institute, which will position UVA at the forefront of cutting-edge medicine such as cellular and gene therapies that could revolutionize how diseases are treated, will use a newly tested geoexchange heating method.

In simple terms, geoexchange involves capturing hot water produced at one time, storing it underground, and later retrieving it to help power systems that provide heating and cooling to a facility, such as the biotechnology institute. The UVA project will capture heat that is generated as a byproduct of air conditioning other University buildings in warmer months, and store it in hundreds of deep, tubelike wells underground, where the steady temperature of the earth will maintain that heated water until it is used to power systems that heat and cool the institute.

The announcement comes four months after UVA workers drilled a series of deep holes around Grounds and determined that the area’s geology is suitable for using the earth as a storage medium for heat.

Paul Zmick, director of energy and utilities at the University, said the project includes construction of a small thermal utility plant to provide heating and cooling to the planned, 300,000-square-foot Manning Institute building. The thermal plant, which will feature between 100 and 200 geoexchange wells to support the biotechnology building, will be the University’s first large-scale geothermal project.