The Row-Tunda finished second, but its crew members still considered it a triumph.

The University of Virginia’s concrete canoe “A Team” was the runner-up in the American Society of Civil Engineers’ Concrete Canoe Competition in Blacksburg, finishing behind Virginia Tech and ahead of Fairmont State University from Fairmont, West Virginia. In total, nine teams competed in the event, held in late March.

“The team was excited to place ahead of Fairmont State, as that team has secured a first-place finish in this competition for more than the last 15 years,” UVA co-captain Leon Crawford said.

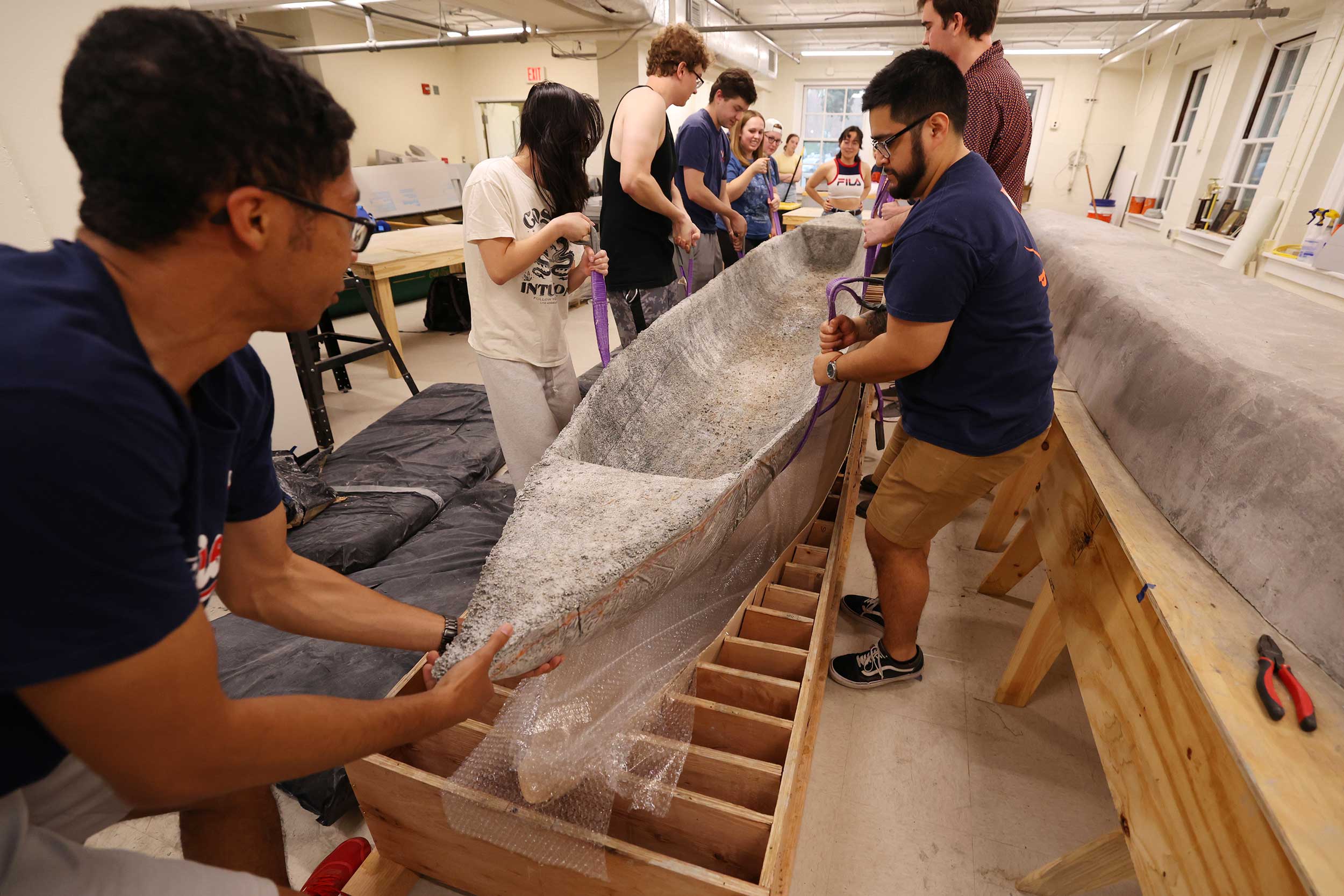

.jpg)