The University of Virginia has acquired two new state-of-the-art three-dimensional bioprinters and has begun training lab scientists and bioengineers to “print” tissues that could eventually be used to treat patients with illnesses and injuries ranging from burns to diabetes, and heart, liver and kidney failure.

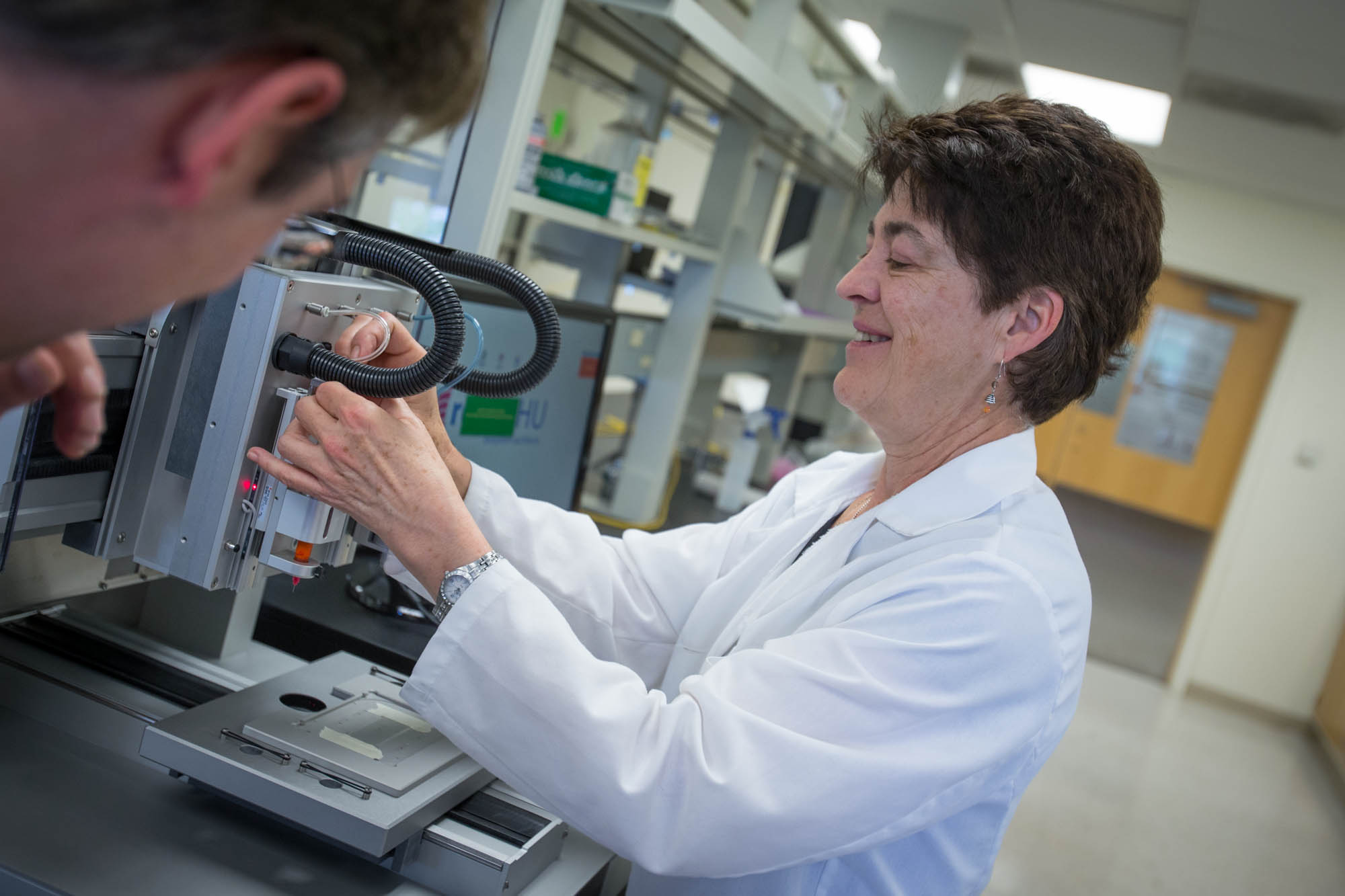

The two bioprinters, manufactured by a leading 3-D bioprinting company, regenHU of Switzerland, are among only four such top-of-the-line machines now in use in the United States. The other two are at medical centers in Boston and Miami.

The printers enable bioengineers to “print” or “draw out” living cells, such as skin or bone or other cell types, onto a substrate, building tissue structure layer by layer, resulting in a custom-designed bit of living material that potentially could be implanted or grafted onto a patient to repair or replace damaged tissue.

The ultimate goal is to eventually fabricate full artificial organs and circumvent the current problem of donor organ shortages.

“In the long run, we hope to develop alternatives to the use of human organs for transplantation,” said Dr. Kenneth Brayman, a transplant surgeon and researcher at the U.Va. School of Medicine who is focusing on the printing of bits of organs and tissues for treating diabetes. “The bioprinter is a tool that can help develop new horizons to address and treat human diseases. The potential for cell therapies is quite high.”

Presently there are numerous applications for 3-D bioprinting, everything from printing skin for burn patients; to printing precisely shaped pieces of collagen, cartilage or muscle for cleft palate repair; to fabricating certain tubular-shaped parts, such as a trachea or a short length of artery. U.Va.’s immediate focus is on printing bits of pancreas for treating diabetes, and bits of skin and muscle for reconstructive surgeries.

“This new capability will in the near term benefit patients being treated at the U.Va. Health System by influencing how doctors think about existing surgical procedures, and in the long term by providing entirely new treatment options for organ transplantation and surgical reconstruction of tissues,” said bioengineering Professor Shayn Peirce-Cottler, whose research program focuses on how blood vessels grow into new and regenerating tissues.

She acquired the two bioprinters – one for her lab in the Department of Biomedical Engineering, and the other for use in Brayman’s lab – with funding primarily from the Office of the Vice President for Research, and additional funding from the School of Engineering and Applied Science. The total cost was $300,000.

Currently, Peirce-Cottler said, the main hindrance to printing complex replacement tissues is the difficulty of providing a sufficient blood supply to the tissue.

“The major design challenge is in printing blood vessels, particularly very small capillaries, which are essential for providing oxygen and nutrients to cells,” Peirce-Cottler said. “The new printers provide a precise level of control in how we can design tissue samples using stem cells. We expect to be able to draw microscopic-sized capillaries into the tissue as we lay out cells.”

Peirce-Cottler noted that the new machines will synergize interdisciplinary research teams consisting of surgeons, engineers and biologists working to implement and test new strategies for designing, growing and regenerating tissue.

“U.Va. has substantial depth of expertise in all of the key areas that are necessary for successfully printing tissues and eventually organs,” she said. “We have collaborative surgeons, such as Dr. Brayman, with exceptional expertise transplanting tissues and organs. We have bioengineers with strong understanding of physiology and anatomy, and our team includes scientists who are successful at developing new therapies to promote tissue growth and regeneration. Plus we have a strong culture of cross- and multi-disciplinary collaboration in close proximity.”

Brayman added, “The presence of the bioprinters in the transplantation and bioengineering laboratories will enable our students and faculty to remain on the cutting edge of such research and enable us to compete for grants and the best and brightest students.”

While bioprinting is cutting-edge technology, it may be some years before the printing of complex organs is possible, Peirce-Cottler cautioned.

“We have to start simple, learn as we go, and then move on to more complicated tissues and organs,” she said. “I think that being able to print an entire multi-structural organ, like a liver, heart or kidney, is probably a long way off, but being able to print smaller, functional, clinically useful pieces of organs or tissues is an obtainable goal in the next few years.”

Media Contact

Article Information

June 2, 2015

/content/uva-acquires-high-end-bioprinters-tissue-organ-fabrication