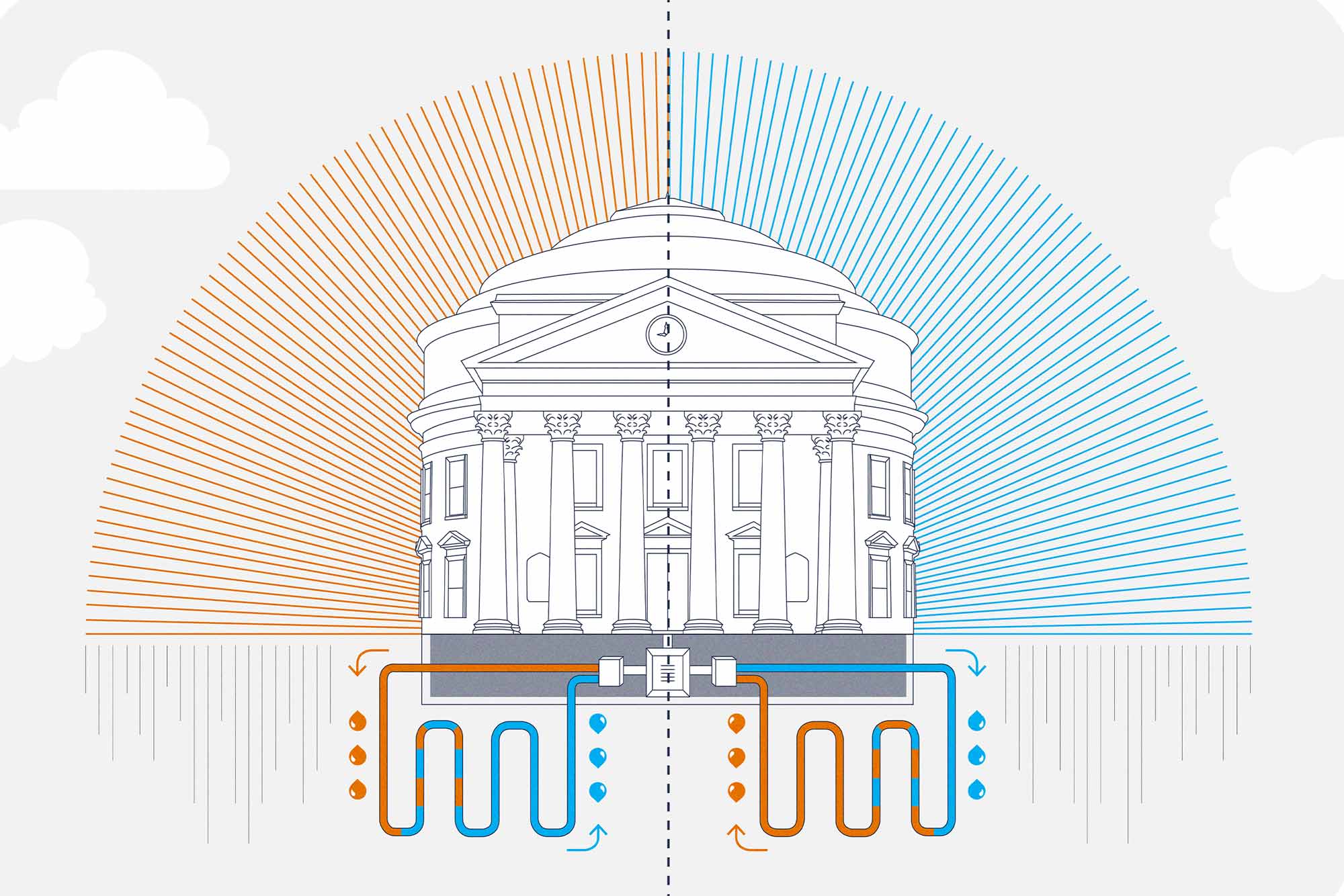

Geoexchange is a hole in the ground in which you store heat. Or, in this case, a hole in the Grounds.

UVA’s Energy and Utilities Department is drilling test holes in the ground under Grounds to measure its viability to store hot air.

Paul Zmick, UVA’s director of energy and utilities, said the seasonal storage will save the University money. (Photo by Dan Addison, University Communications)

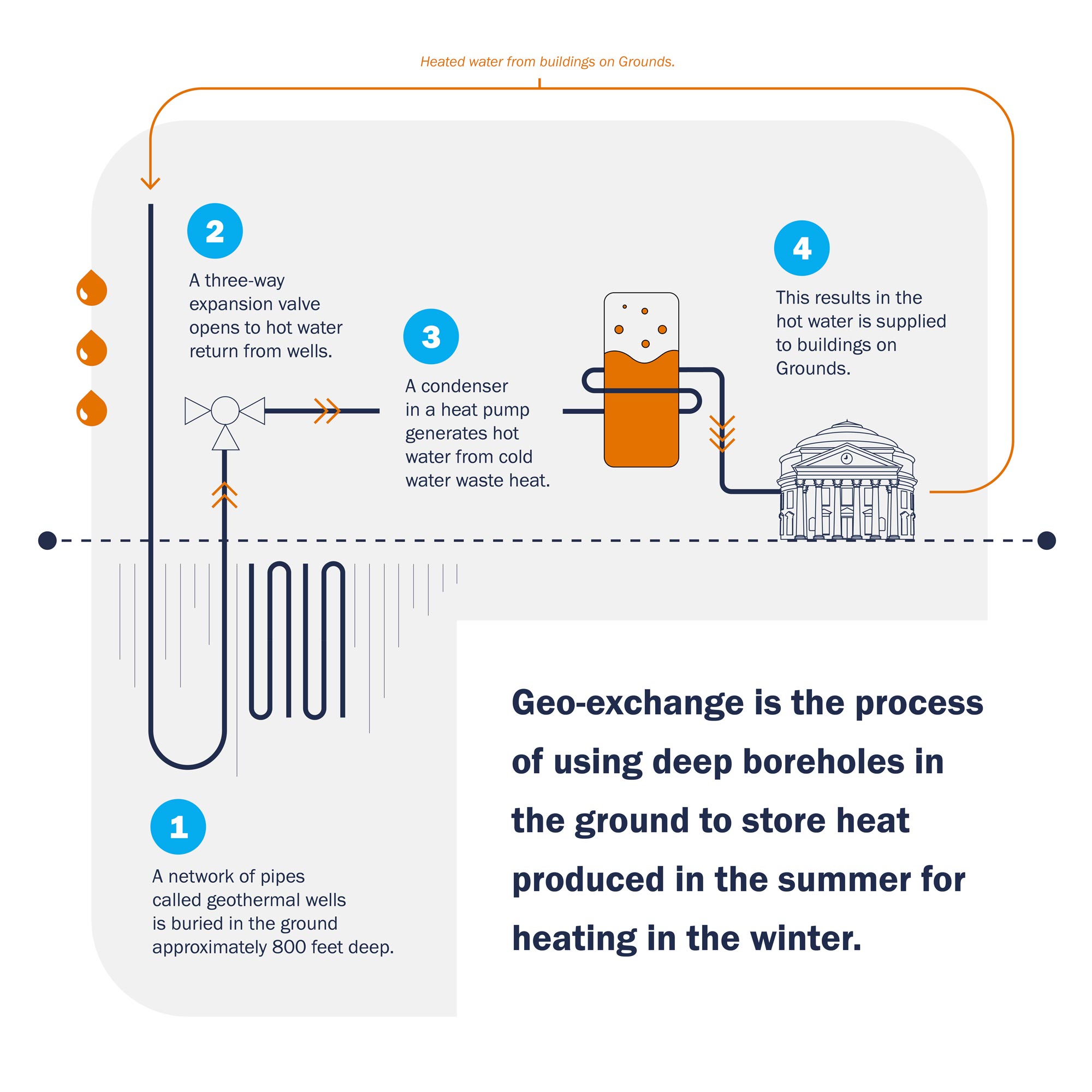

“Geoexchange is the process of using deep boreholes in the ground to store heat produced in the summer for heating in the winter,” said Paul Zmick, director of energy and utilities. “This is commonly called seasonal storage.

“In order to design geoexchange systems, we require a detailed understanding of the heat capacity and geology for the specific areas being considered for large bore fields.”

To get that information, Zmick and his team are drilling eight test holes, each up to 8 inches in diameter and as deep as 1,000 feet. Six of the wells will be used for thermal testing. Later, workers will insert a tube into each hole and fill the space surrounding the tube with conductive grout. Then they will run hot water down into the tubes for a couple of days to test the heat retention of the soil.

Zmick said it would take several days to determine if a well had potential for the geoexchange project.

Depending on the soil’s heat-holding capacity, the wells could be spaced closer together or farther apart to optimize the system, Zmick said.

A successful seasonal storage plan will save the University money and reduce its carbon footprint, Zmick said.

Currently, the University heats water using conventional fuels in boiler plants. The hot water is circulated to buildings, where the heat is extracted through HVAC or radiant systems; the cooled water is then returned to the plant through a closed loop. In the summer, the buildings are cooled using chilled water.

The process of keeping University buildings cool in the summer produces heat that currently is vented away. But that heat could be captured and stored in deep underground wells to warm buildings in the winter. (Infographic by Meredith Michael Smith, University Communications)

Zmick envisions a different approach.

“In the proposed system, heat recovery chillers combined with geoexchange, will use electricity to drive the chiller that will produce both hot and cold water,” Zmick said, noting chillers produce hot water the way a freezer generates heat while creating ice.

“It is a vapor compression and expansion process using refrigerants similar to household heat pumps,” Zmick said.

Geoexchange solves a problem facing most renewable energy - storage. Like a large thermal battery, the ground can store the heat for a long time, from six months to a year, due to the relatively slow groundwater flow through the soil.

“In the middle of summer, when we are making a lot of chilled water and we need somewhere to dump the heat off the hot side, we can dump it down a well,” Zmick said. “And we are just heating that soil around the well we drilled, and so in the wintertime when we are making a lot of chilled water and we need more hot water, we can pull it out and use it to heat buildings.”

Two studies on Grounds, conducted by Affiliated Engineers Inc. and FVB Energy, recommended geoexchange coupled with heat recovery chillers as a decarbonization strategy.

“By coupling the heat recovery chillers to geoexchange, we can have a system that is extremely efficient,” Zmick said. “And it can operate year-round because the closed-loop geoexchange systems operate most efficiently when we have both a heating and cooling load. You don’t want to overheat it or overcool it. You want to create this balanced geoexchange field that stores just enough heat to help you get through winter and stores enough cooling to get you through summer.”

The combination of the systems increases the base efficiency.

“A chiller is about 300% efficient, which means for every unit of electricity in, we get three units of energy out,” Zmick said. “When we capture the heat that is typically rejected in the cooling towers, we get an additional 300% efficiency.”

![] Ray Carpenter, Richard Hopkins and Jason Yowell work with equipment to drill a well](/sites/default/files/Inline_03_Paul_Zmick-Geo-Exchange_Test_Bores_05_DA.jpg)

Ray Carpenter, Richard Hopkins and Jason Yowell work on the drill site at the Fontaine Research Park. (Photo by Dan Addison, University Communications)

Richard Hopkins of Wilson Well Drilling from Ruckersville drilled the first test hole at the southeast edge of the Fontaine Research Park parking lot, reaching 600 feet in two days. The rig rattled a little as the drill bit encountered granite and sandstone, layers which were expected, according to Paul Stevens, an engineering and energy systems manager at Facilities Management.

“We have to let the wells sit for five to seven days so the heat from the boring can dissipate,” Zmick said. “Then we will connect the thermal test unit to the bores and gain insight into the thermal conductivity and heat storage capacity of each well.”

The test bores provide information for larger potential projects in the future, Zmick said.

“Our first production bore field will be associated with a new plant that we are building at Fontaine to support the biotech building and eventually the entire precinct,” he said. “This production field will be completed in 2024.”

Two wells will be used for geophysical testing, looking more specifically at the geology layer by layer. Zmick said the rock underneath Grounds is believed to be heavy in graphite, which he said could increase its heat retention by 30 times.

The other test bores will be drilled near the Leake Building; outside the parking lot at The Park; near the Afghan Kabob restaurant, adjacent to the Lambeth Field apartments; at the Emmet-Ivy Corridor construction site; just north of Carr’s Hill field; just outside the parking lot at Scott Stadium; and at Nameless Field.

Once the testing is over, at least one well will remain accessible for academic research, Zmick said.

Media Contact

University News Associate Office of University Communications

mkelly@virginia.edu (434) 924-7291

Article Information

August 18, 2025