As part of a new NASA-funded study, the team published data this summer in the journal Aerospace Science and Technology showing, for the first time, that airflow in supersonic combustion jet engines can be controlled by an optical sensor.

The finding could lead to more efficient stabilization of hypersonic jet aircraft, allowing new opportunities to break Earth’s bounds.

“One of our national aerospace priorities since the 1960s has been to build single-stage-to-orbit aircraft that fly into space from horizontal takeoff like a traditional aircraft and land on the ground like a traditional aircraft,” professor Christopher Goyne, director of the UVA Aerospace Research Laboratory, said. “Currently, the most state-of-the-art craft is the SpaceX Starship. It has two stages, with vertical launch and landing. But to optimize safety, convenience and reusability, the aerospace community would like to build something more like a 737.”

The now-retired space shuttle largely mastered half the problem, the gliding-back-to-a-runway part. But the shuttle launched vertically attached to mammoth, volatile and expensive rockets.

To reach those high speeds, a space plane would need a different engine, something scientists call a “scramjet.” These “air breathing” engines use oxygen forced in during flight to combust safer hydrocarbon-based fuels. The engines can be throttled back, too, rather than running only at full blast.

Scramjet engines have been demonstrated to fly up to Mach 10 – that’s 10 times the speed of sound, or more than 7,600 mph – but only for a matter of seconds. The intense shock waves produced at hypersonic speeds – Mach 5 and greater – have prevented control of longer flights.

Previously, scramjets used pressure sensors to obtain information about shock impact at the engine’s walls. The optical sensor, however, can identify more subtle changes, both inside the engine and within the flow path.

The tool analyzes the amount of light emitted by a source – in this case, the reacting gases within the scramjet combustor – as well as other factors, such as the flame’s location and its spectrum of light.

“The light emitted by the flame within the engine is due to relaxation of molecular species that re-excited during combustion processes,” explained Laurie Elkowitz, a doctoral student on the project. “Different species emit light at different energies, or colors, offering new information about the engine’s state that is not captured by pressure sensors.”

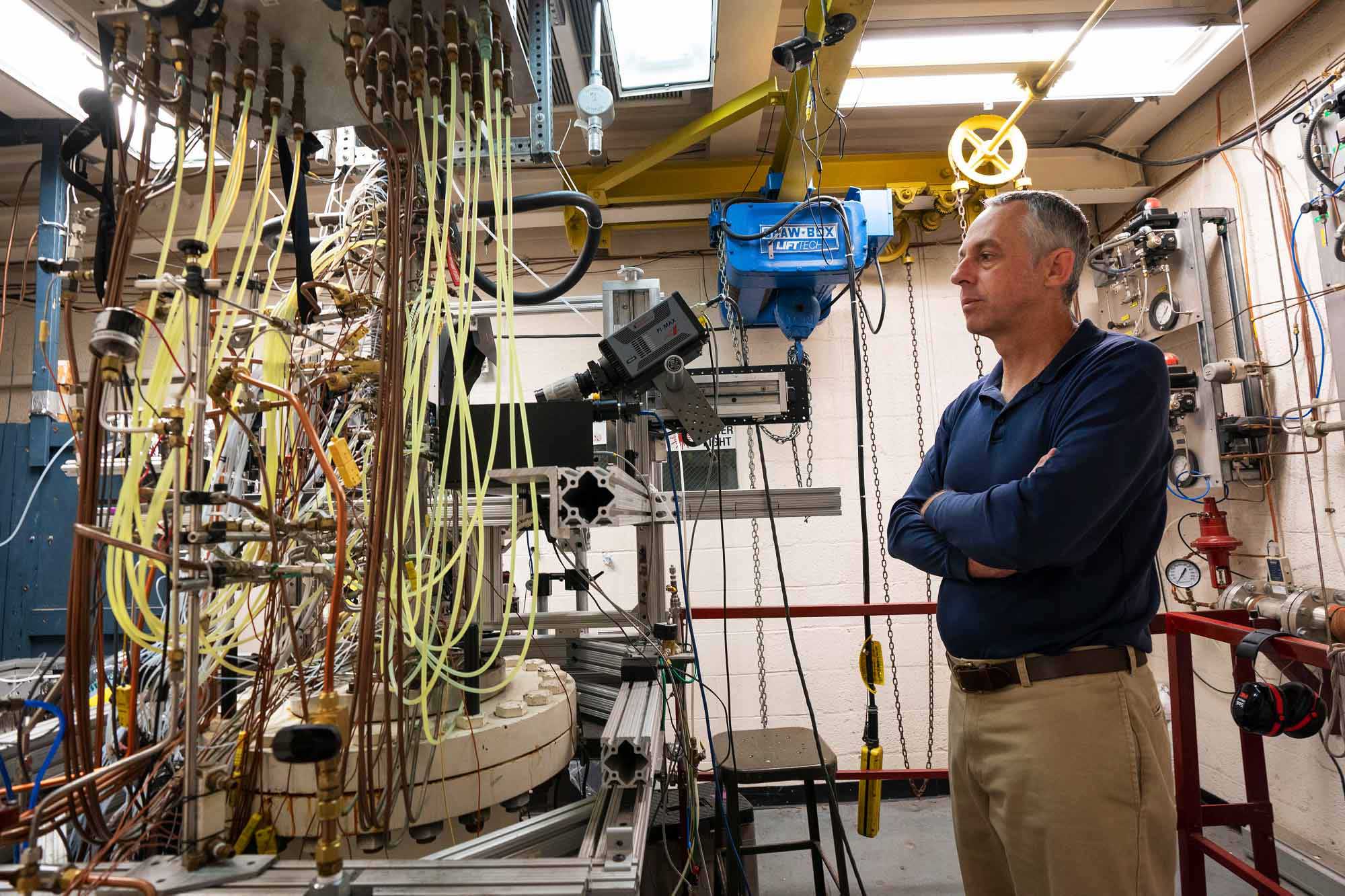

Goyne oversaw the control aspect of the study, while co-investigator Chloe Dedic, a UVA Engineering associate professor, oversaw the optical sensor development. The work was supported by a NASA grant, led by Timothée Pourpoint of Purdue University.

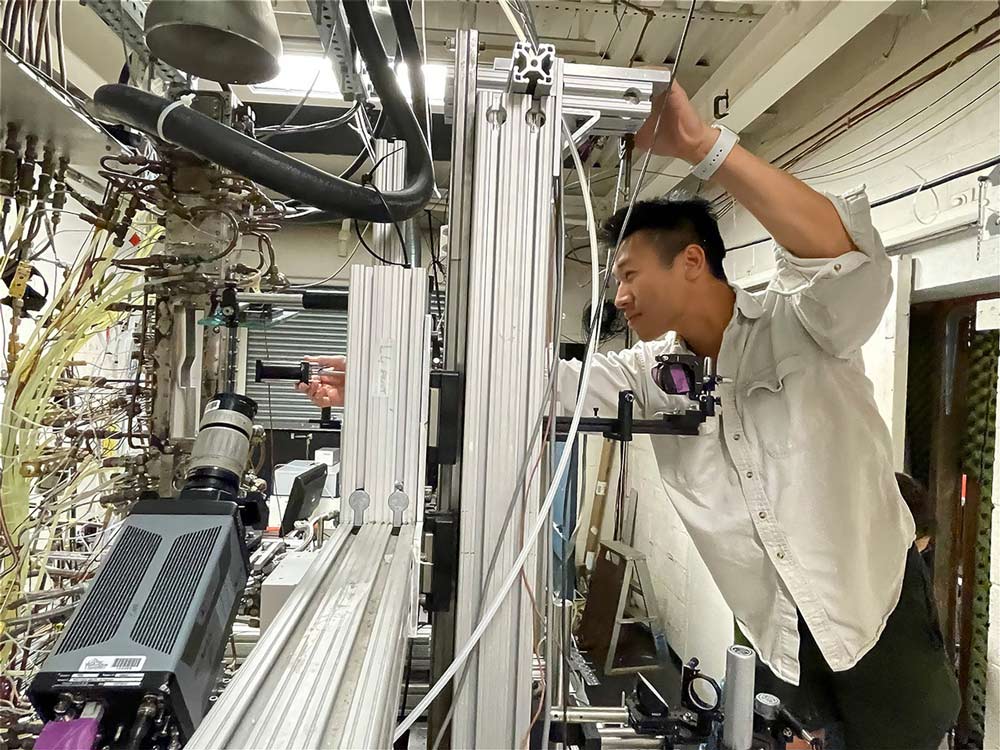

The team used UVA’s Supersonic Combustion Facility, which can simulate engine conditions for a hypersonic vehicle traveling at Mach 5, for the study. The team tested an optical emission spectroscopy sensor for the feedback needed to control the lab-created shock waves.

The team’s wind tunnel demonstration showed that the engine control can be both predictive and adaptive, smoothly transitioning from ramjet functioning – the technology that the fastest operational jets and missiles currently use – to scramjet engine mode and continued operation, despite changes in dynamics.

“We were very excited to demonstrate the role optical sensors may play in the control of future hypersonic vehicles,” doctoral student Max Chern, the paper’s first author, said. “We are continuing to test sensor configurations as we work toward a prototype that optimizes package volume and weight for flight environments.”

While more work remains to be done, optical sensors may be a component of the space flight future Goyne believes will be realized in his lifetime. Dual-mode scramjets would still require a boost of some sort to get the aircraft to at least Mach 4. But an all-in-one aircraft, which would glide back to Earth like the space shuttles once did, might provide the ideal combination of cost-efficiency, safety and reusability.

“I think it’s possible, yeah,” Goyne said. “While the commercial space industry has been able to lower costs through some reusability, they haven’t yet captured the aircraft-like operations.”

Read more at the UVA Engineering website.