A material found in the claws of squid scratching for prey in the frigid depths of the ocean could be the future of keeping homes toasty on land.

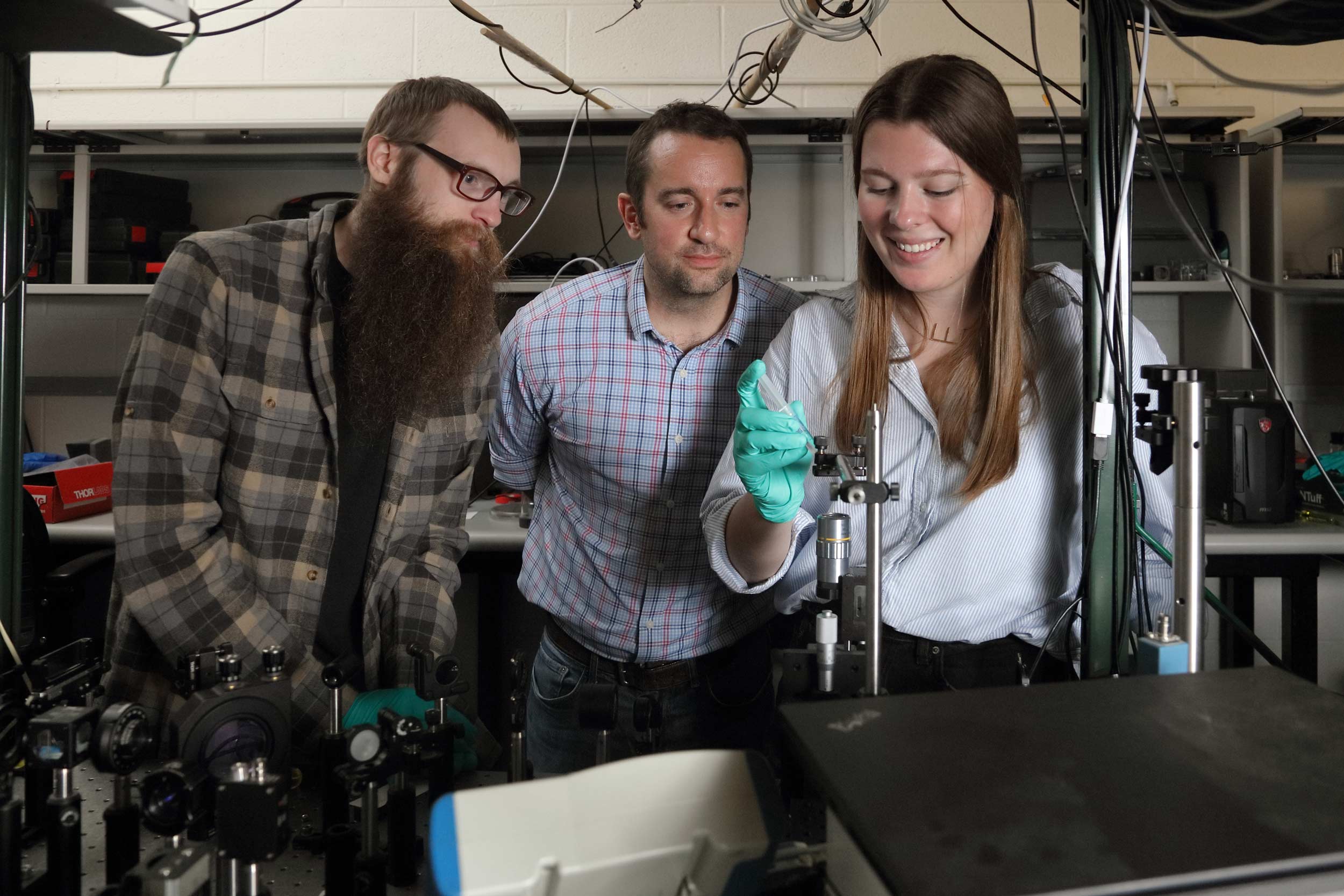

The University of Virginia recently led a successful project for the U.S. Department of Energy that indicates synthesized squid-claw protein, also known as “squid ring teeth” protein, could serve as an effective medium for thermal batteries and residential heating.

The protein can retain large amounts of heat until activated by water, which allows the structure to cohere, forming a pathway for the energy to move.

“We met all the metrics,” said Patrick Hopkins, a UVA mechanical and aerospace engineer who served as principal investigator on the project. “What this is opening up now is a new class of batteries for thermal energy storage.”

The biologically based synthetic protein is non-toxic, non-corrosive and non-flammable. And it can be manufactured via a “carbon circular process,” eliminating environmental impact.