If you have loved ones who are immunocompromised or not yet eligible for a COVID-19 vaccine, you know the problem: They need to wear high-quality masks for safety, but the masks can be uncomfortable and make it hard to breathe.

Ongoing mask dilemmas, made worse by the lightning spread of the virus’ omicron variant, gave new urgency to the work of Gaurav “Gino” Giri, an assistant professor of chemical engineering at the University of Virginia. Giri’s lab at the School of Engineering and Applied Science is developing an alternative mask technology – work that got a boost from The Ivy Foundation’s COVID-19 Translational Research Fund and The Jefferson Trust in 2020.

Giri’s team is patenting a process for turning ordinary fabrics into inexpensive, washable air filters that breathe as easily as plain cloth masks, but are much better at stopping fine particle matter and other airborne hazards. He and his colleagues at Hava Inc., the company he co-founded with UVA assistant professor of public policy Balashankar Mulloth, anticipate releasing their first run of 5,000 face masks with Giri’s technology as early as March.

The team hopes that by then, the Hava masks will be certified under a new standard established in February 2021 by the American Society for Testing and Materials International for breathability and filtration efficiency. The standard applies to face coverings that are not medical masks or respirators.

Gaurav Giri, right, co-founded Hava Inc. with UVA colleague Balashankar Mulloth to develop technology with the potential to dramatically improve the air filtration efficiency and breathability of face masks. (Photo by Dan Addison, University Communications)

N95 masks remain the gold standard in air filtration for personal protective equipment, filtering 95% of particles down to 0.3 microns in size – about 200 times smaller than the diameter of human hair. While the coronavirus is smaller than that at about 0.1 micron, it is typically attached to the water droplets or mucus we breathe out, which, like most particulate matter in air pollution, range from 1 to 4 microns or larger.

The U.S. Centers for Disease Control and Prevention advises that wearing highly protective masks such as N95s “may be most important for certain higher risk situations, or by some people at increased risk for severe disease,” but those types of masks “may be harder to tolerate or wear consistently than others.” The CDC guidelines state that for people who are not at increased risk and for non-medical situations: “It is most important to wear a well-fitted mask or respirator correctly that is comfortable for you and that provides good protection.”

While N95 masks are now widely available, Hava’s research revealed people overwhelmingly prefer cloth masks for breathability and comfort, Giri said.

The American Society for Testing and Materials’ specifications were developed in response to the COVID-19 pandemic to address what was a “Wild West of PPE” resulting from the lack of any standards for cloth masks, Giri said.

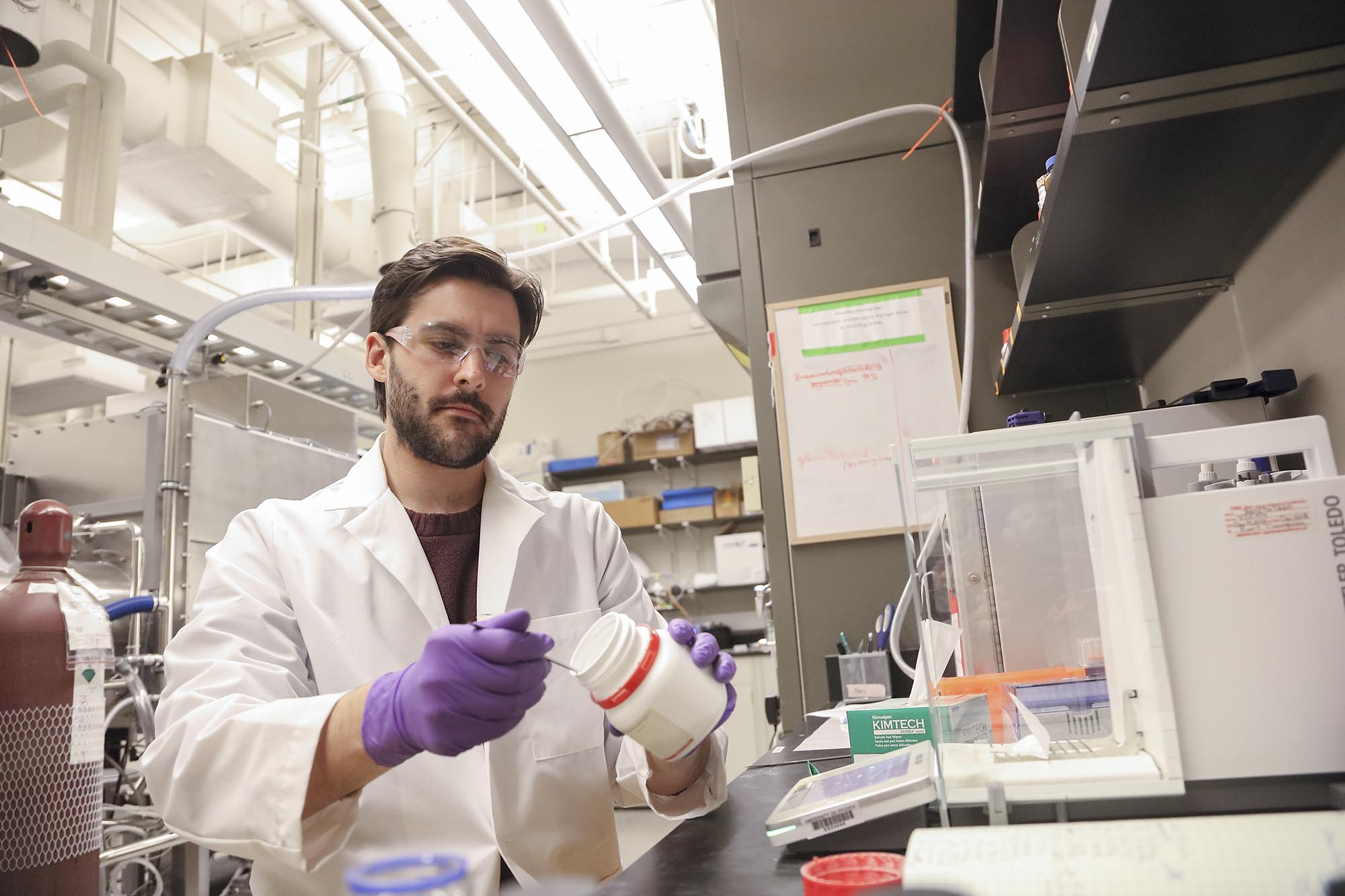

Gaurav Giri checks in with undergraduate research assistant Emily Beyer, who has been involved in Giri’s metal-organic frameworks research program since her first year at UVA Engineering. (Photo by Tom Cogill)

The standard sets two levels of certification for materials that filter tiny particles: Level 1 is 20% and above filtration, and level 2 is 50% and above filtration. In internal lab tests, using a polyester fabric for optimum softness and air flow, Giri so far has achieved greater than 40% filtration for coronavirus-sized particles.

The standard also sets two levels for breathability, determined by measurements of airflow resistance. The specified performance values are designed for the general public.

“Both levels require a lower filtration efficacy but have a more stringent standard for breathability than the standards required for N95 masks,” Giri said. “To our knowledge, there are very few masks that are fabric-based, without extra insert filters, that pass the ASTM level 1 standard, and none that are fully washable and reusable.

“Currently, our masks pass level 1 in both standards at lab scale. With this initial run of 5,000 masks, we are trying to show that large-scale production also passes these standards.”