Patients who walk into Dr. Jose Gurrola II’s otolaryngology clinic at the University of Virginia Health System are seeking relief from a wide range of nasal issues, from nosebleeds and chronic sinusitis to brain fluid leaks.

To assess the patients and determine the best course of action, Gurrola or a member of his team may perform an endoscopy – a procedure that involves taking a camera with a long scope on the end and inserting it into a patient’s nasal cavity.

It’s seldom a welcomed prospect, Gurrola acknowledged. “Most patients are not used to having something in their nose, so they may be very nervous,” he said.

Similarly, newly minted residents may have some uneasiness before performing the procedure on a patient for the first time.

Gurrola says the 3-D-printed models provide an important training bridge between books and bedside.

“It can be completely unnerving for the patient and the resident,” Gurrola said.

But a recent development at UVA is creating new opportunities that bolster the confidence of both patients and residents in the otolaryngology department.

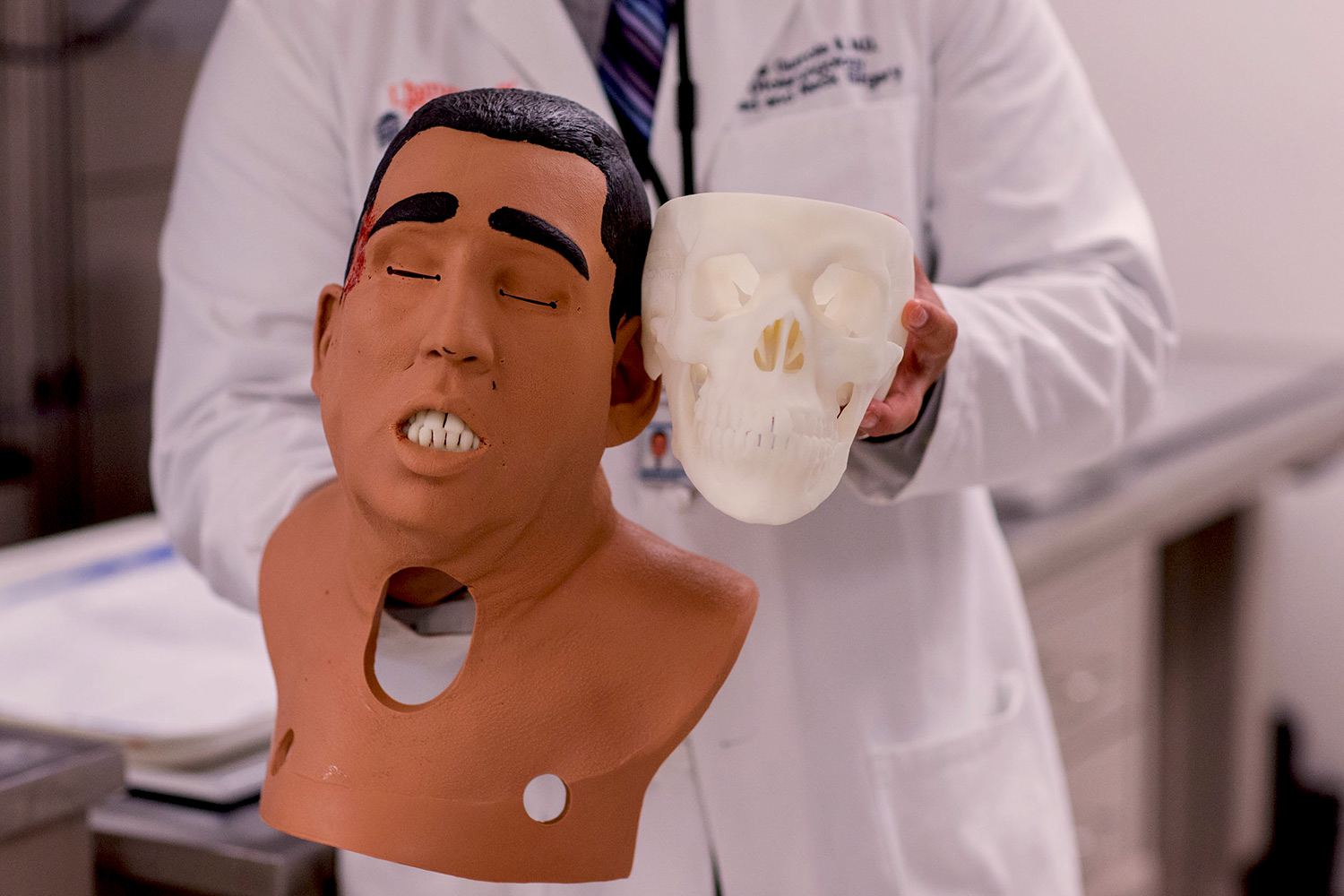

Gurrola, a nose specialist, along with Dr. Robert Reed, an otolaryngology resident, and Dwight Dart, a design lab engineer at the UVA School of Engineering and Applied Science’s Rapid Prototyping 3-D Printing Lab, have created 3-D-printed skulls to use as models for rhinological surgical simulation using a combination of software and hardware.

To create the models, a patient’s CT or MRI scans are converted to 3-D printable files, which are then printed on a 3-D printer.

“The models allow students, residents and doctors to see, feel and understand dimensions of real human geometry,” Dart said.

According to Gurrola, the benefits of the 3-D models are plentiful; they are relatively cheap to produce, reusable and readily accessible to trainees.

Patient CT or MRI scans are converted to 3-D printable files to create the 3-D printed skull models.

The 3-D printed skulls are just one of several medical projects to come out of the Rapid Prototyping Lab since its opening five years ago. “3-D printing is going to revolutionize medicine,” Dart said.

The model skulls “are available to students or doctors in affiliated programs, such as neurosurgery, whenever they want it,” Gurrola said. “This allows our UVA trainees to gain significant endoscopy experience early on and throughout their career.”

During Gurrola’s own time as a trainee, he and his fellow residents would practice performing endoscopies using the “buddy system.”

“Students and residents in the same class would take turns ‘scoping each other,” Gurrola said. “You wanted to make sure you didn’t hurt the other person too much, because they were going to ’scope you right after.”

After moving into his role as a surgeon and teacher, Gurrola let his students practice the procedure on him.

“It wasn’t always comfortable,” he said. “And I didn’t like the idea of my patients having to experience that, but I knew that we still needed a way to train the residents.”

A facial mask is placed over the skull models to make them more closely resemble a live patient.

Gurrola used his knowledge of 3-D printing technology and his personal experiences to brainstorm a new method that would unify the medical center’s goals of advancing the training and education of residents and maintaining patient safety and satisfaction.

“We’re using next-generation technology today to meet the realization of our goals in terms of improving our learning opportunities for our trainees while ensuring that our patients continue to get world-class care,” Gurrola said.

Reed believes that the 3-D models, which were funded by the School of Medicine’s Graduate Medical Education Innovation Grant, can transform surgical training and become a beneficial mode of practice.

“For the most part, surgical training is still a process where trainees pass through a continuum that still looks a lot like the ‘see one, do one, teach one’ model of old,” he said. “Our hope is that with the continued development of simulations such as this, we can improve upon this model.”

Moving forward, Gurrola and Dart foresee potential advancements – like implanting sensors and fluid flow lines that would allow the models to react similarly to human geometry – that could lend themselves to even more opportunities for doctors and trainees across medical departments.

“For those patient cases that may be unique or different, the 3-D models should be able to provide us with the option of examining that particular anatomy,” Gurrola said.

Gurrola said projects like the 3-D printed models are what allow him and his team to achieve their ultimate goal and priority.

“One of the most rewarding experiences is to see the amazing smile that’s generated after we ask a patient who hasn’t breathed well for years to take a deep breath, and they realize they’re finally able to breathe well through their nose again,” he said. “From my perspective, providing world-class care for our patients while allowing our trainees to develop into tomorrow’s world-class physicians is a winning situation for all of us.”

Media Contact

Article Information

July 18, 2016

/content/3-d-printed-skulls-prepare-new-doctors-while-promoting-world-class-health-care