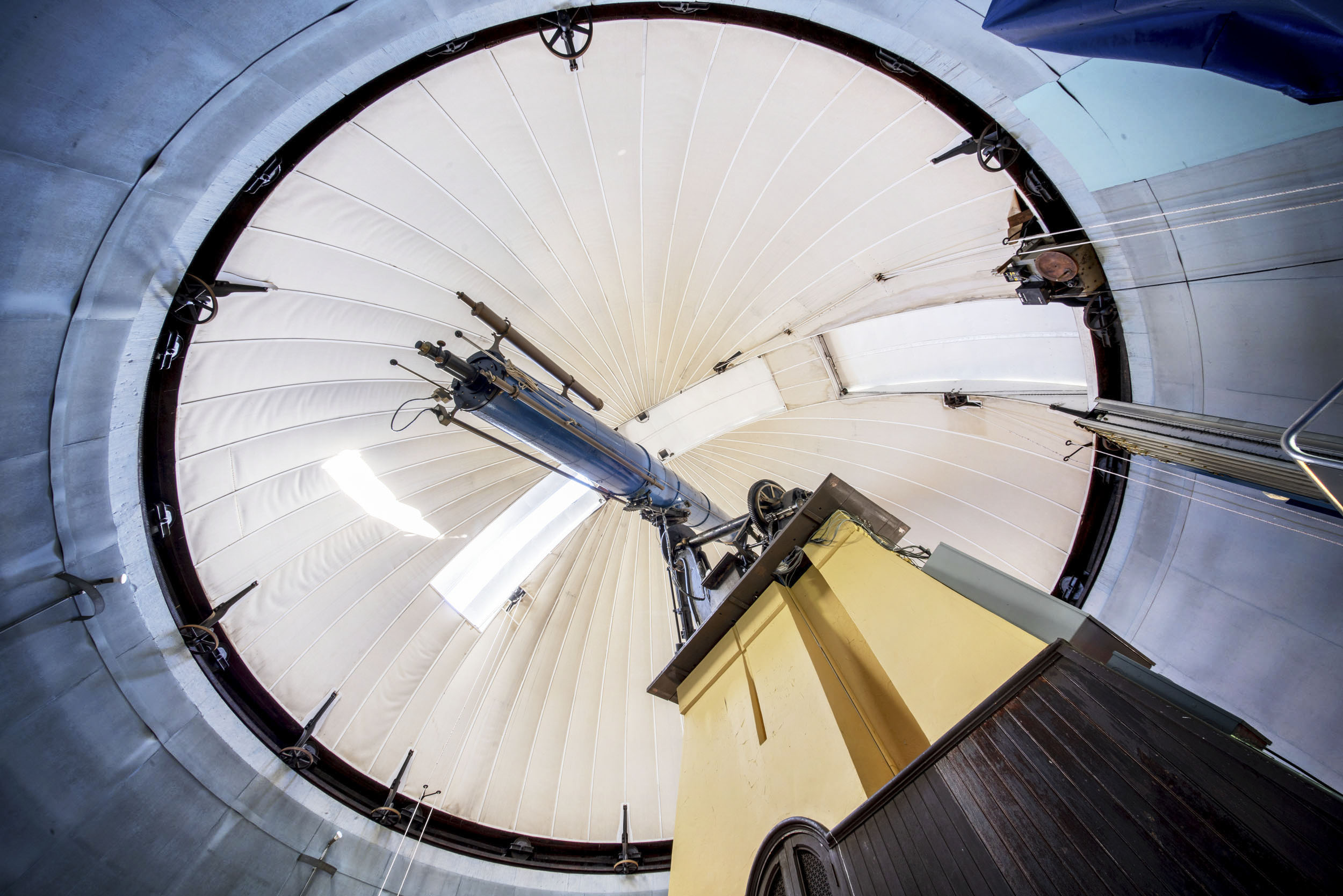

The sliding doors on the University of Virginia’s McCormick Observatory dome are back on track.

The observatory’s dome, built in 1884 by Warner and Swasey Company of Cleveland and dedicated in 1885, has three slits that allow the telescope to peer out at the heavens. Each opening is covered by two shutters that ride on a series of rollers at the top and bottom of each shutter. The observer uses a rope to pull the shutters open manually, as has been done since the observatory’s dedication.

“Over the last decade, the shutters have been getting harder and harder to open,” astronomy professor Edward Murphy said. “This was due, in large part, to the rollers and the track that they ride on. The track has been painted many times over the years and is no longer smooth. It was also covered in debris.”

The rollers, and the bearings inside, were original equipment.

“About two years ago, the astronomy department came to us and said the shutters weren’t working properly,” said Henry Hull, a historic preservation project manager with Facilities Management. “They were worried about the water getting in, affecting the telescope and getting into the interior of the dome.”