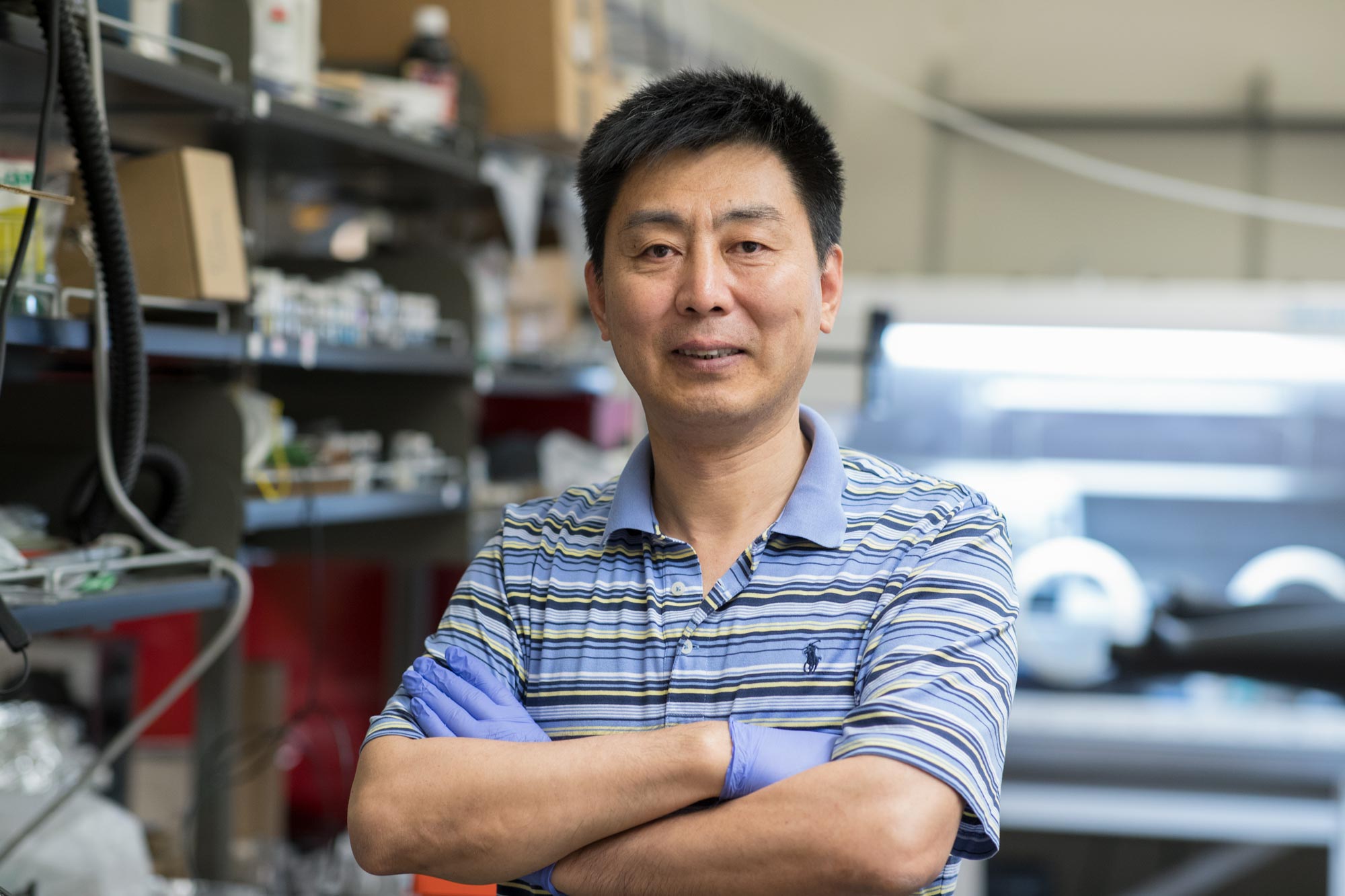

“Manufacturing is experiencing an evolutionary moment with the sophistication of 3-D printers,” said Li, Rolls-Royce Commonwealth Professor of mechanical and aerospace engineering. “Yet as good as they are, they inherently create products with flaws. As such, they can’t be relied on to create parts for critical devices.

“We are designing smart machines that can create flawless products.”

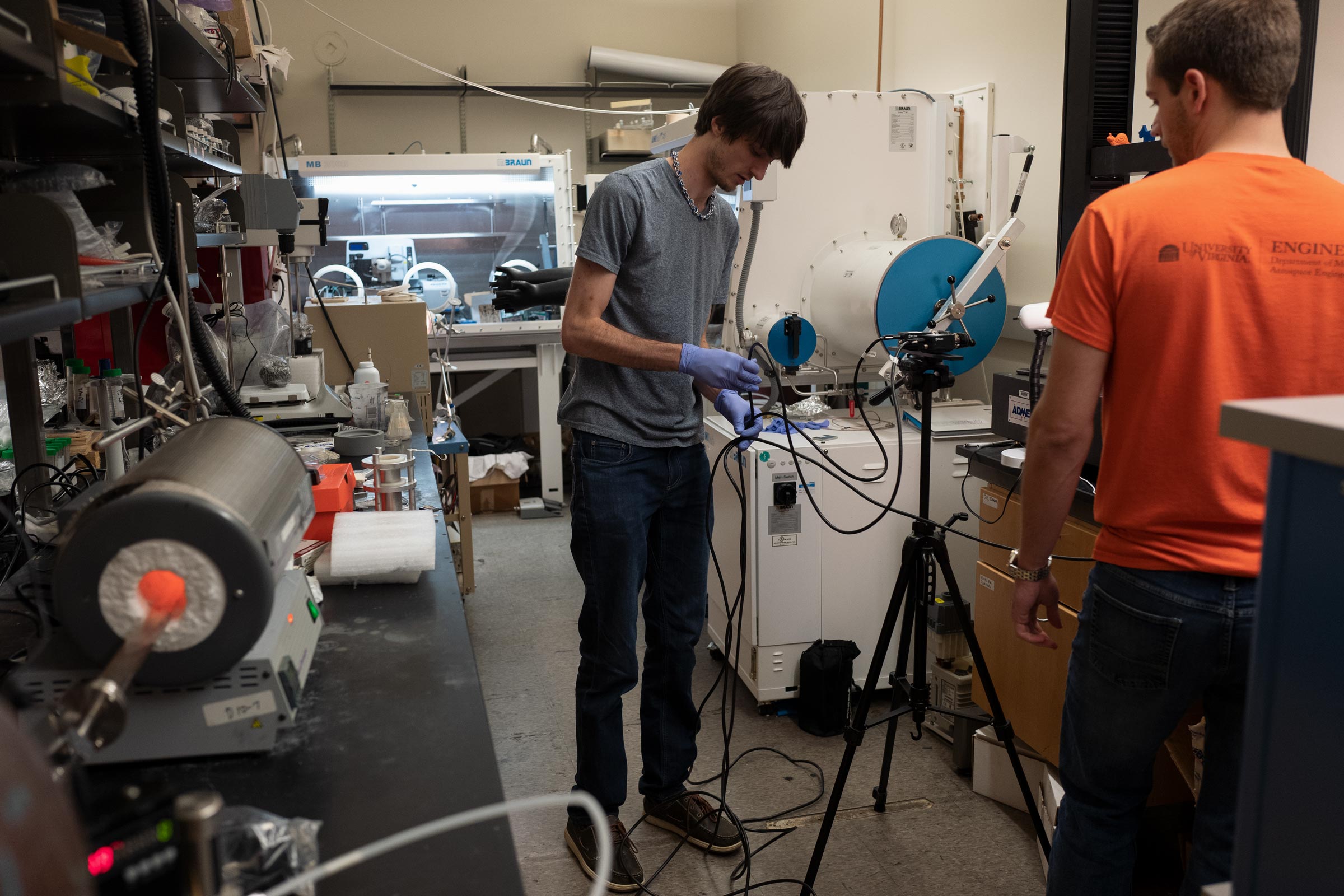

For about four years, Holzmond, Bartlett and Li have been working on their system to help 3-D printers make perfect products with fewer resources and virtually no waste, all in a fraction of the time it takes to make the same products today. In addition, the system will be able to learn from its mistakes, be resilient to hacking and train other machines.

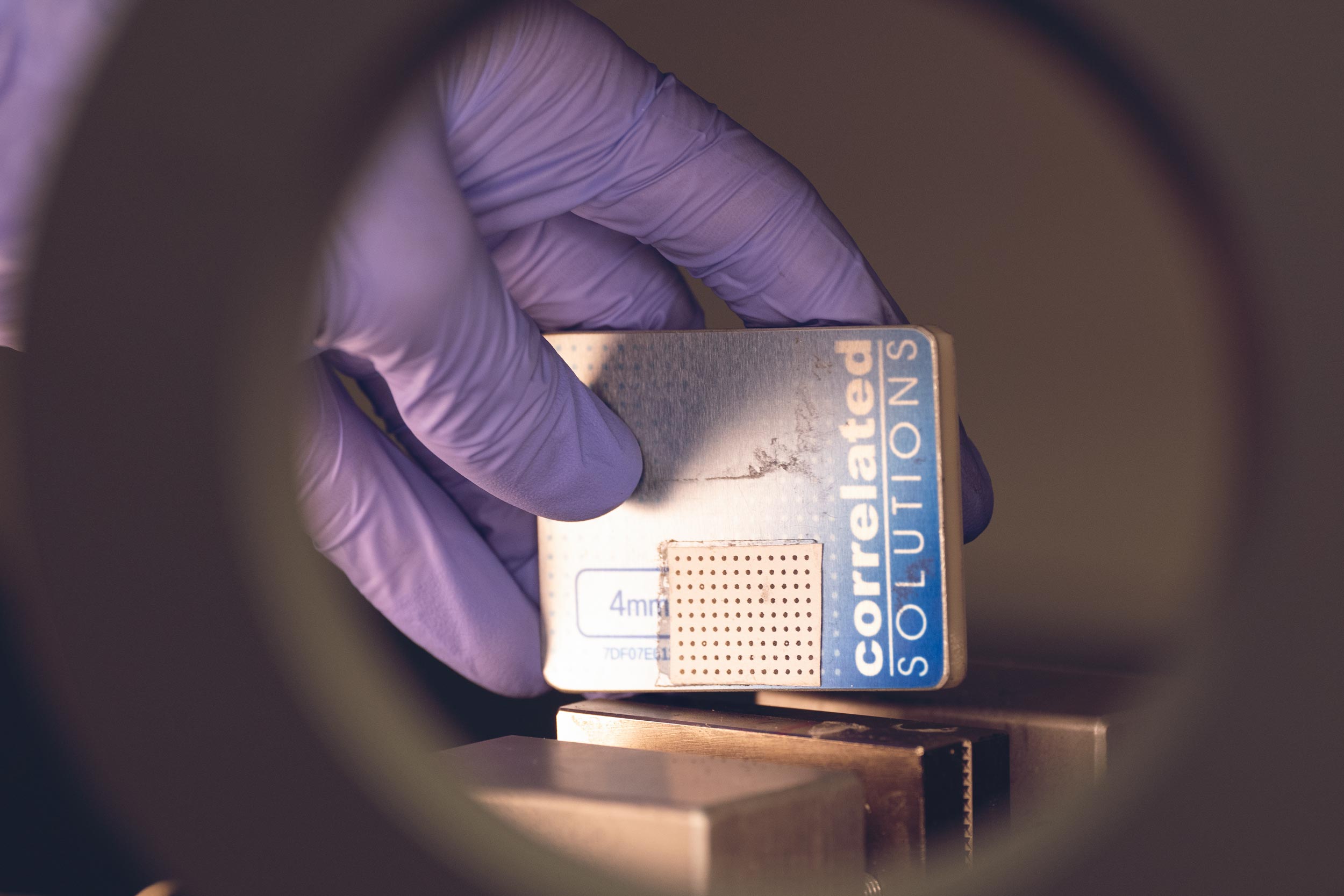

“Humans use all of their senses to inform their decisions. We are bringing that same perspective to machines,” Li said. “We have created optical sensors, or eyes, capable of seeing down to the micron level, and infrared and auditory sensors that assess temperatures and can hear reverberations. And then, of course, we have created a ‘brain,’ a computer code that can process all this information in real time to make immediate decisions about how to address a problem.”

It is no overstatement to say that these are major breakthroughs in machine learning and advanced manufacturing. The technological advances Li and his students are making have the potential to pay huge dividends in increased efficiency and reduced waste in the $12 trillion manufacturing industry, and ultimately benefit society in almost every way.

“We have strengths in additive manufacturing, machine learning and artificial intelligence, and decades of experience in sensor technology here at UVA Engineering, and we are leveraging that knowledge in a way that will transform the manufacturing industry,” Li said.