The “Internet of Things” needs energy-efficient hardware, some of which may come from research developed at the University of Virginia School of Engineering and Applied Science’s affiliate of the MIST Center.

MIST – short for “multifunctional integrated systems technology” – is a center at the University of Florida that connects faculty members and students with industry in an effort to solve practical problems. UVA is one of three sites, with the University of Florida and the University of Central Florida, together forming a National Science Foundation-supported Industry-University Cooperative Research Center.

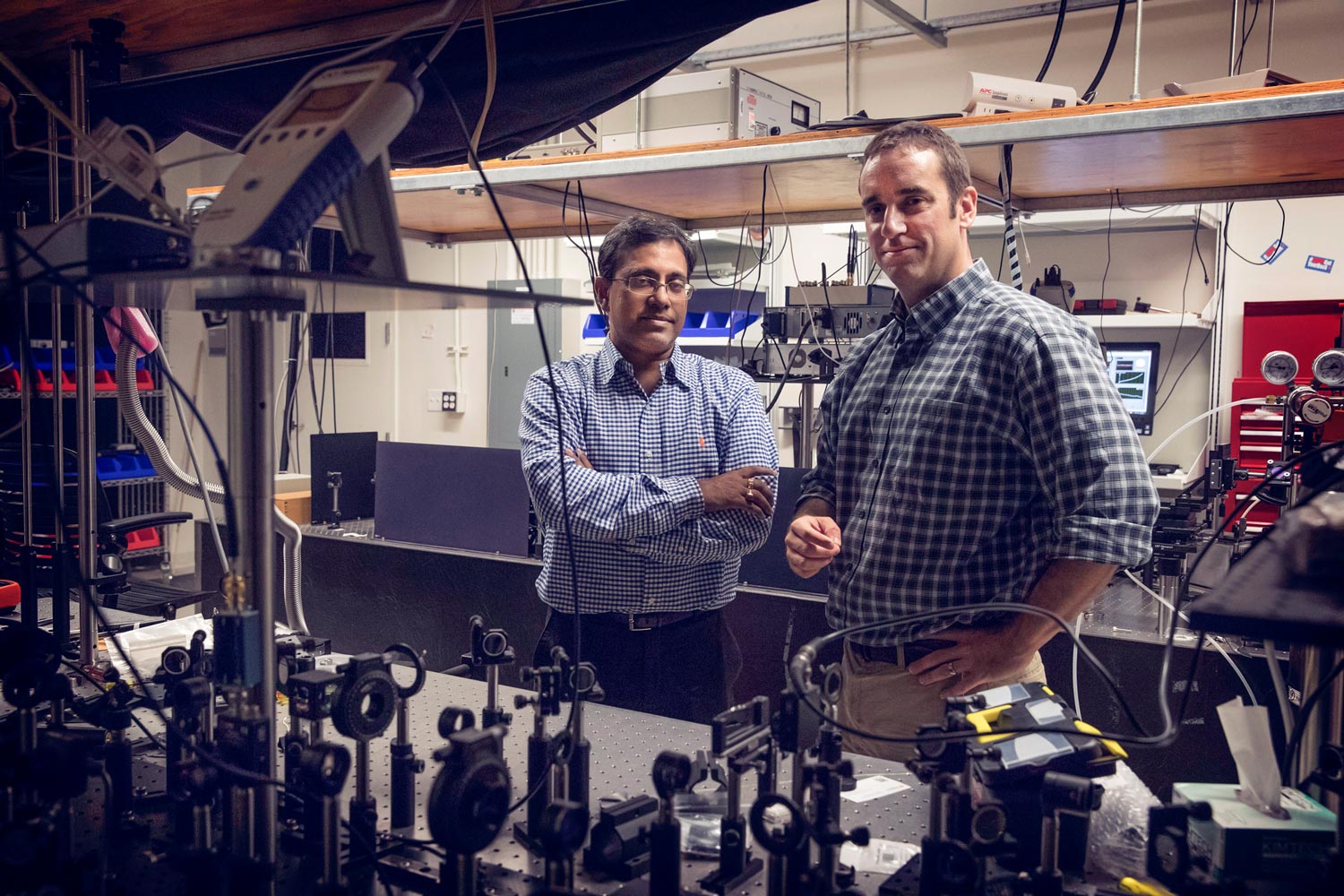

The sites engage in work that goes beyond fundamental research, but which is not quite ready to roll out as a product, said Avik Ghosh, an electrical and computer engineering professor with a joint appointment in physics, who directs the MIST Center’s UVA site. Companies and research labs pay to be members of the center and work with MIST researchers.

“Today you have the Internet of Things, portable devices that go around the block communicating with each other through the cloud – your cellphone communicating with your thermostat, for example,” Ghosh said. “More and more companies are investing in the IoT, such as sensors that communicate through the cloud.

“One area MIST focuses on is bringing these sensors closer to hardware, away from the cloud and onto the actual chip. In other words, we wish to explore ways of bringing hardware and software closer together, the sensor nearer the processor – to allow on-chip computing that is energy-efficient, instant, compact, lightweight and not limited by access to Wi-Fi with its associated cybersecurity issues.”

Such a sensor hardware interface will involve algorithm-driven applications that learn to predict outcomes in real time and act on these predictions.

“An example of an end-user application would be a smart camera that knows where to focus, such as in an autonomous unidentified vehicle, or perhaps a wearable device that can learn in real time and make instant decisions on when to inject glucose into a diabetic patient without the need to communicate with the cloud,” Ghosh said. “That is the kind of end-user products that can be enabled by developing energy-efficient hardware for the IoT, the overall goal of our MIST Center.”

Ghosh’s computational group develops quantum transport models that connect emerging materials to devices in order to address industrial needs.

Patrick Hopkins, a professor of mechanical and aerospace engineering with appointments in materials engineering and physics, also co-directs UVA’s MIST site. Hopkins, whose research centers on heat transfer in nanomaterials and across interfaces, is fascinated by the interaction of academic research and industrial requirements.

“It is not an opportunity that we get often,” Hopkins said of working with industry. “A traditional route to supporting research at UVA and at most academic institutions is applying for government grants and doing sponsored research. The pace of industry is much faster; the research is much more targeted.”

“This center is a good fit for UVA Engineering because of the school’s focus around three primary areas of research strength: engineering for health, engineering for the cyber future and engineering technologies for a sustainable and connected world,” said Susan L.R. Barker, the school’s associate dean of research. “Our researchers seek opportunities to produce tangible value for society, and that is an important benefit for companies that need cutting-edge technologies to remain competitive.”

Hopkins’ students share his enthusiasm, since they can see concrete benefits.

“My students absolutely love working with industry because they actually say, ‘If I do this, that could go into the iPhone,’ or ‘That would make a better battery that would go into your computer,’” Hopkins said. “They can see a direct link. They see that end product, which is enabled by working with industry.”

While specific researchers work with specific companies, all the companies in the consortium share in the research and all the companies vote on selecting the next round of projects.

There are four outside partners working with the researchers at the UVA site: the U.S. Army Research Lab, Night Vision Labs, L3 Technologies and DRS Technologies.

“Those companies buy a membership to be part of that group and they advise you on research projects and help to steer you in the direction of technologically relevant things that you should be trying,” Hopkins said. “These are problems they are looking to solve, and we have capabilities and expertise here.”

Ghosh noted all four of the outside partners at the UVA site are military-related, but said there are consumer firms involved in the centers as well, including Allegro, Corning and Boeing.

“We are doing what is called ‘pre-competitive research,’” Ghosh said. “For example, a particular industry is interested in a particular product and wants us to test some components or concepts that are critical for them to understand this path through transition. And our goal is to work with industry to try to find what their needs are.”

Each outside partner pays approximately $50,000 per year for each project, while the universities reduce their overhead down to 10 percent, which works out to about one graduate student per project. In addition, NSF provides money to allow operational costs such as organizing biannual meetings.

“Each project cost is not large enough to build a product, but it is large enough to test some components, do a proof-of-concept analysis, and give industry some ideas about the next steps toward productive allotment,” Ghosh said. “And one of the ideas of the [Industry-University Cooperative Research Center] is ultimately they want to see things like patents, invention disclosures and start-up spinoffs, which take these precompetitive concepts further.”

The students also see an opportunity for employment.

“Companies are very active and outgoing in saying it is a successful project if they can hire a well-trained Ph.D. student who can come work with them, either as an intern or join their company afterward,” Hopkins said. “They are looking for recruitment.

“If you think about it, for a company, this is a no-brainer way to recruit. You basically groom a student for however long you are going to be funding them and they are up to speed on your technology. They’ve been doing cutting-edge research on the company’s technology.”

All the members get access to all the research, while working closely with the researchers they have funded.

“The entire research portfolio of the three universities together is over $1 million per year, so for $50,000 apiece, member organizations are getting access to the non-exclusive, royalty-free intellectual property – knowledge basically of about $1 million or more of research, plus access to several faculty and students,” Ghosh said. “That is the return on investment for them. And more than 90 percent of the money goes directly into research.”

Some of the research the professors and the graduate students conduct relates to energy transfer across the interfaces of the nano-scale hardware.

“If you look at the chips under an electron microscope, you have billions and billions of little transistors, billions and billions of little calculators,” Hopkins said. “And all of those calculators are connected together onto an integrated circuit. Every one of those connection points is an interface. Every one of those connection points is impeding heat transfer from where it is generated in the calculator to the eventual heat sink, which is a microscopic part of this device. We want to help manipulate interfaces, design interfaces based on their atomic structure to get rid of that thermal resistance.”

Hopkins’ research has been focused on reducing the resistance to heat transfer at the interfaces.

“When you put two materials together, the interface between those two materials gives a large thermal resistance,” Hopkins said. “So there are a large amount of temperature increases that can occur at interfaces.”

But surprisingly, one company in the consortium wanted more heat, not less, because it helped with the company’s sensor performance. Hopkins said the frequent contact between the companies and researchers can change the direction of some research.

“With the interaction with the companies, you end up having this dialogue, this back and forth, and realize solution pathways you never thought were important before,” Hopkins said.

There are six funded MIST research projects at UVA. In addition to Hopkins working on interfaces, Ghosh is working with Mircea Stan, a professor in the Department of Electrical and Computer Engineering, on neuron-inspired algorithms that would be able to learn, predict outcomes and make decisions.

“It is brain-inspired computing ideas where we have signals with significant and meaningful time-varying components, for example in video data,” said Samiran Ganguly, a research scientist in Ghosh’s group. “We have set up a machine-learning and signal-processing framework that can filter dynamic distortions/noise from images, recognize user-defined features and then track them in a video stream by learning and predicting long-term patterns in time.

“Video processing for IoT applications goes beyond automated cars and drones to a wide range of fields, such as developing tools for efficient and semi-automated analysis of vital bio-physical signals, and creating early warning systems for health care delivery, such as early prediction of heart attacks, glycemic shock and neurological disorders, based on these tools.”

Joe Campbell, a professor of electrical and computer engineering, is working on silicon carbide-based avalanche photo diodes, which refers to a few electrons that can create a lot of electrons to ramp up sensitivity and detect laser-induced fluorescence from biological agents.

Nikhil Shukla, an assistant professor in the electrical and computer engineering department, is working on reconfigurable antennas for wireless applications using phase change materials.

Steven Bowers, an assistant professor of electrical and computer engineering, is working on high-dynamic-range power amplifiers for ultra-low power devices such as sensors.

The opportunities of the MIST Center are open to all researchers at the University.

“It is a constant recruiting process,” Ghosh said. “We have all these different topics and we are constantly sending out messages to faculty. It is not meant to be exclusive. It’s open to any faculty member who believes his or her research could be of interest in this conduit for bringing industry and academia together and who can bring interested industry partners to the table.”

Ghosh said faculty members are alerted to MIST Center meetings and any with a project can submit it.

“And the industries are going to prioritize, saying this is the one we are going to fund, and those are the ones we don’t want to fund at the moment,” Ghosh said. “And that is determined partly by interest and partly by available dollars. But the center facilitates this intersection between industry guys and our faculty and our students.”

Media Contact

Article Information

October 12, 2018

/content/researchers-mist-uva-faculty-work-advance-internet-things